Product Description

Product Description

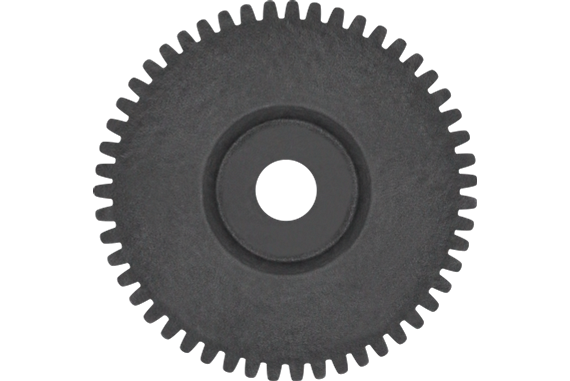

| 1. High quality materials, professional production, high-precision equipment. Customized design and processing; |

| 2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties; |

| 3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption; |

| 4. Focus on gear processing for 35 years. |

| 5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity; |

| 6. The tooth surface can be ground, and the precision is higher after grinding. |

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

ZheJiang Province Tonging Auto Synchronizer Co., Ltd and ZheJiang Shshi Xihu (West Lake) Dis.g Gears Co. Ltd are focus on the production of space parts for the CHINAMFG over 35years. a professional company in the field.

Our spare parts are interchangeable with the major manufacturers of heavy duty trucks, buses, light commercial and 4×4 pick up vehicles, medium and heavy duty Japanese applications. New items developing for customized in earthmover and agriculture machines.

There are 1 forging production line of 1600 tons, several forging production lines from 400 tons to 1000 tons: more than 300 various manufacturing and inspecting equipments with high efficiency and precision; 2 heat treatment production lines.

Our company can achieve more production process of forging, hobbing, shaving, gear

shaping, grinding and heat treatment.

There are 4 factories affiliated to the company, including Gear Factory, Synchronizer Factory, Adjusting Arm Factory and Casting Factory, producing various Transmission Synchronizers;

Differential Gears; Cross Spiders; Differential cases and other parts. We produce those parts for various types of

domestic trucks, Japanese trucks, European trucks and other famous brands. Moreover, the Agriculture machinery gears and Engineering machinery gears can developing also.

As a member of China Gear Industry Association and China

Auto Gear Manufacture Association, our company always focuses

on technology and quality. The company is an AAA enterprise, got lATF16949:2016 Quality Management System Certificate and has been awarded as Honest and Faithful Company several times by

government. Our products occupy large share of China and we established cooperation relations with CHINAMFG Group. Meanwhile, our products become very popular in Southeast Asia, Europe. Middle

East, Russia, America and other foreign countries.

With superior quality and excellent service, we are ready to offer

our products and service to costumers of all over the world!

Material: 20CrMnTiH

Scope and Capability of Gear Processing:

Modulus 1 to 10

Grade 6 of grinding accuracy

Grade 8 of accuracy achieved by shaving

Maximum machining diameter 400mm

Heat treatment: Quenching and tempering +carburizing

Gearboxes

Input shafts

Gears

Sliding sleeves

Hubs and synchronizer cones

Planet carriers

Housing

Differentials

Loaded differential cases

Idler pinions and side gears

Gears

Differential kits

Differential Input Shafts

FAQ

| Q1. What is your terms of packing? |

| A: Generally, we pack our goods in Crates/Pallet/Boxes/Cartons. |

| Q2. How about your delivery time? |

| A: Generally, it is 3-7days if the goods are in stock,or it is need 20-30days to producing, |

| it is according to the quantity. |

| Q3. Can you produce according to the samples? |

| A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures. |

| Q4. Do you test all your goods before delivery? |

| A: Yes, we have 100% test before delivery |

| Q5.Do you provide samples?is it free or extra? |

| A:yes,we could offer the sample for free,but do not pay the cost of freight. |

| Q6.What is your term of payment |

| A:payment less than 3000usd,100% in advance,payment more than 6000usd,30%payment before produce,70% balance payment before shipment. |

| Application: | Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you retrofit an existing mechanical system with spur gears?

Retrofitting an existing mechanical system with spur gears involves modifying or replacing certain components to incorporate spur gears into the system. Here’s a detailed explanation:

1. Evaluate the Existing System:

Begin by thoroughly evaluating the existing mechanical system to determine its design, function, and limitations. Identify the specific components that need to be retrofitted with spur gears and understand how the system operates.

2. Design Considerations:

Based on the evaluation, consider the design considerations for integrating spur gears into the system. This includes factors such as gear size, tooth profile, gear material, gear ratio, and torque requirements. Determine the specific gear specifications that are compatible with the existing system.

3. Gear Selection:

Select the appropriate spur gears that meet the required specifications. Consider factors such as gear quality, load capacity, noise level, efficiency, and compatibility with the existing system components. Choose gears from reputable manufacturers or consult with a gear specialist for guidance.

4. Gear Positioning and Alignment:

Determine the optimal positioning and alignment of the spur gears within the existing system. This involves identifying the gear locations, shaft connections, and ensuring proper alignment with other components such as bearings and couplings. Accurate positioning and alignment are crucial for efficient gear operation and longevity.

5. Modification or Replacement:

Based on the design considerations and gear selection, proceed with the necessary modifications or replacements. This may involve removing existing components, such as gears with different tooth profiles, and replacing them with the selected spur gears. Ensure proper installation and secure attachment of the new gears.

6. Lubrication and Maintenance:

Implement appropriate lubrication practices for the newly retrofitted spur gears. Consult gear manufacturers’ recommendations for lubricant type, quantity, and maintenance intervals. Proper lubrication ensures smooth gear operation, reduces wear, and extends gear life.

7. Testing and Validation:

After the retrofitting process, conduct thorough testing and validation of the modified system. Verify that the spur gears are functioning as intended, ensuring proper engagement, smooth operation, and adequate load handling. Address any issues or discrepancies discovered during testing.

8. Documentation and Training:

Create documentation detailing the retrofitting process, including gear specifications, installation procedures, and maintenance requirements. This documentation serves as a reference for future maintenance and helps ensure consistent gear performance. Additionally, provide training to relevant personnel on the operation, maintenance, and troubleshooting of the retrofitted system.

Retrofitting an existing mechanical system with spur gears requires careful planning, proper gear selection, precise installation, and thorough testing. By following these steps and considering the specific requirements of the system, it is possible to successfully incorporate spur gears and enhance the performance and functionality of the mechanical system.

How do you prevent backlash and gear play in a spur gear mechanism?

Preventing backlash and gear play is crucial for maintaining the accuracy, efficiency, and smooth operation of a spur gear mechanism. Here’s a detailed explanation of how to prevent backlash and gear play in a spur gear mechanism:

- Precision Gear Design: Ensure that the spur gears used in the mechanism are designed with precision and manufactured to tight tolerances. Accurate tooth profiles, proper tooth spacing, and correct gear meshing are essential to minimize backlash and gear play.

- Adequate Gear Tooth Contact: Optimize the gear meshing by ensuring sufficient tooth contact between the mating gears. This can be achieved by adjusting the center distance between the gears, selecting appropriate gear module or pitch, and ensuring proper gear alignment.

- Proper Gear Engagement Sequence: In multi-gear systems, ensure that the gears engage in a proper sequence to minimize backlash. This can be achieved by using idler gears or arranging the gears in a way that ensures sequential engagement, reducing the overall amount of play in the system.

- Backlash Compensation: Implement backlash compensation techniques such as preloading or using anti-backlash devices. Preloading involves applying a slight tension or compression force on the gears to minimize the free movement between the gear teeth. Anti-backlash devices, such as split gears or spring-loaded mechanisms, can also be used to reduce or eliminate backlash.

- Accurate Gear Alignment: Proper alignment of the gears is critical to minimize gear play. Ensure that the gears are aligned concentrically and parallel to their respective shafts. Misalignment can result in increased backlash and gear play.

- High-Quality Bearings: Use high-quality bearings that provide precise support and minimize axial and radial play. Proper bearing selection and installation can significantly reduce gear play and improve the overall performance of the gear mechanism.

- Appropriate Lubrication: Ensure that the gears are properly lubricated with the correct type and amount of lubricant. Adequate lubrication reduces friction and wear, helping to maintain gear meshing accuracy and minimize backlash.

- Maintain Proper Gear Clearances: Check and maintain the appropriate clearances between the gears and other components in the gear mechanism. Excessive clearances can lead to increased gear play and backlash. Regular inspections and adjustments are necessary to ensure optimal clearances.

- Regular Maintenance: Implement a regular maintenance schedule to inspect, clean, and lubricate the gear mechanism. This helps identify and rectify any issues that may contribute to backlash or gear play, ensuring the gear system operates at its best performance.

By following these practices, it is possible to minimize backlash and gear play in a spur gear mechanism, resulting in improved precision, efficiency, and reliability of the system.

It’s important to note that the specific techniques and approaches to prevent backlash and gear play may vary depending on the application, gear type, and design requirements. Consulting with gear manufacturers or specialists can provide further guidance on addressing backlash and gear play in specific gear mechanisms.

What is a spur gear and how does it work?

A spur gear is a type of cylindrical gear with straight teeth that are parallel to the gear axis. It is one of the most common and simplest types of gears used in various mechanical systems. Spur gears work by meshing together to transmit rotational motion and torque between two parallel shafts. Here’s a detailed explanation of spur gears and how they work:

A spur gear consists of two or more gears with cylindrical shapes and an equal number of teeth. These gears are mounted on parallel shafts, and their teeth mesh together to transfer rotational motion from one gear to another. The gear with power input is called the “drive gear” or “driver,” while the gear receiving the power output is called the “driven gear” or “follower.”

The key characteristics and components of spur gears include:

- Teeth: Spur gears have straight teeth that are cut parallel to the shaft axis. The teeth are evenly spaced around the circumference of the gear. The number of teeth determines the gear ratio and affects the speed and torque transmission between the gears.

- Pitch Diameter: The pitch diameter is the theoretical diameter of the gear at the point where the teeth mesh. It is determined by the number of teeth and the module or diametral pitch of the gear.

- Module or Diametral Pitch: The module is a parameter used in metric gear systems, while the diametral pitch is used in imperial gear systems. They define the tooth size and spacing of the gear. The module is the ratio of the pitch diameter to the number of teeth, while the diametral pitch is the number of teeth per inch of pitch diameter.

- Pressure Angle: The pressure angle is the angle between the line tangent to the tooth profile at the pitch point and a line perpendicular to the gear axis. Common pressure angles for spur gears are 20 degrees and 14.5 degrees.

- Meshing: Spur gears mesh by engaging their teeth, creating a point or line contact between the contacting surfaces. The teeth transfer rotational motion and torque from the drive gear to the driven gear.

- Gear Ratio: The gear ratio is determined by the number of teeth on the drive gear and the driven gear. It defines the relationship between the input speed and the output speed. The gear ratio can be calculated by dividing the number of teeth on the driven gear by the number of teeth on the drive gear.

- Operation: As the drive gear rotates, its teeth come into contact with the teeth of the driven gear. The contact between the teeth transfers rotational motion and torque from the drive gear to the driven gear. The meshing teeth maintain a constant speed ratio, allowing for the transmission of power between the shafts. The direction of rotation can be changed by meshing gears with an odd or even number of teeth.

Spur gears offer several advantages, including simplicity, ease of manufacture, efficiency, and reliability. They are commonly used in a wide range of applications, including machinery, automotive systems, appliances, power tools, and more.

In conclusion, spur gears are cylindrical gears with straight teeth that mesh together to transfer rotational motion and torque between parallel shafts. Their simple and efficient design makes them a popular choice for various mechanical systems.

editor by CX 2023-10-16